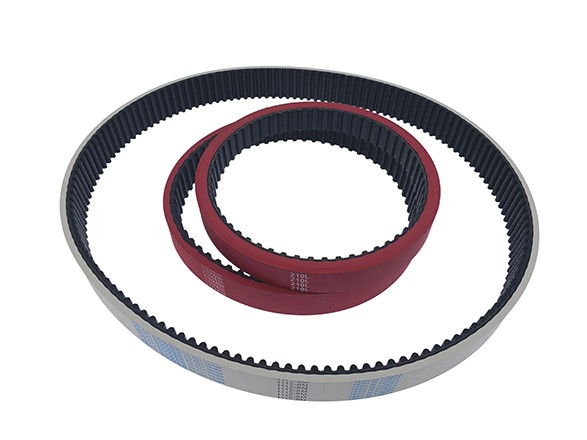

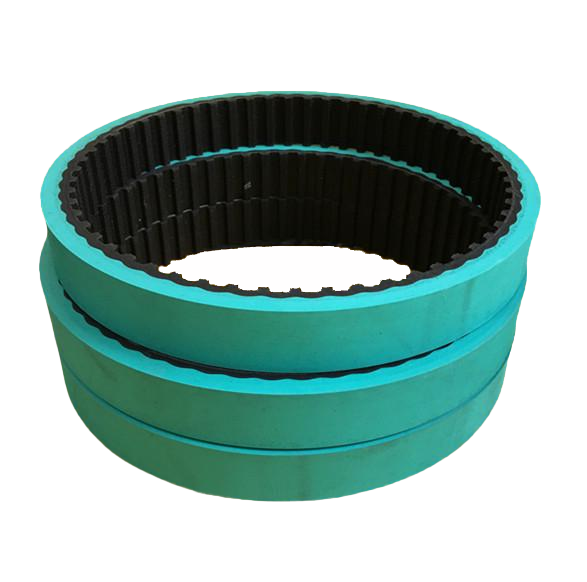

Rubber Coated Timing Belts

CONSTRUCTION:

Neoprene+polyester cord

FEATURE:

Reliable transmission and dimensional stability, low pre-tension, low noise, good elasticity, high wear resistance, anti-aging, water-repellent, anti-ultraviolet, anti-ozone, anti-oil ester, anti-corrosion of most acids and alkalis, can be combined with other heat Plastic material combination.

APPLICATION:

Due to the high friction and high temperature resistance of rubber, rubber coated timing belt products can be used in a variety of conveying applications: paper industry, ceramic industry, wood processing, glass manufacturing, labeling and packaging equipment.

Model | Step (mm) | Tooth (mm) | Thickness (mm) | Angle(β°) | |||||

MXL | 2.032 | 0.51 | 1.14 | 40 | |||||

XXL | 3.175 | 0.76 | 1.52 | 50 | |||||

XL | 5.08 | 1.27 | 2.3 | 50 | |||||

L | 9.525 | 1.91 | 3.6 | 40 | |||||

H | 12.7 | 2.29 | 4.3 | 40 | |||||

XH | 22.225 | 6.35 | 11.2 | 40 | |||||

XXH | 31.75 | 9.53 | 15.7 | 40 | |||||

T2.5 | 2.5 | 0.7 | 1.3 | 40 | |||||

T5 | 5 | 1.2 | 2.2 | 40 | |||||

T10 | 10 | 2.5 | 4.5 | 40 | |||||

T20 | 20 | 5 | 8 | 40 | |||||

AT5 | 5 | 1.2 | 2.7 | 50 | |||||

AT10 | 10 | 2.5 | 5 | 50 | |||||

AT20 | 20 | 5 | 8 | 50 | |||||

Model | Step (mm) | Tooth (mm) | Thickness (mm) | ||||||

HTD | 2M | 2 | 0.75 | 1.36 | |||||

3M | 3 | 1.17 | 2.4 | ||||||

5M | 5 | 2.06 | 3.8 | ||||||

8M | 8 | 3.36 | 6 | ||||||

14M | 14 | 6.02 | 10 | ||||||

20M | 20 | 8.4 | 13.2 | ||||||

STD/STS | S2M | 2 | 0.76 | 1.36 | |||||

S3M | 3 | 1.14 | 2.2 | ||||||

S4.5M | 4.5 | 1.71 | 2.81 | ||||||

S5M | 5 | 1.91 | 3.4 | ||||||

S8M | 8 | 3.05 | 5.3 | ||||||

S14M | 14 | 5.3 | 10.2 | ||||||

RPP | 2M | 2 | 0.76 | 1.36 | |||||

3M | 3 | 1.15 | 1.9 | ||||||

5M | 5 | 1.95 | 3.5 | ||||||

8M | 8 | 3.2 | 5.5 | ||||||

14M | 14 | 6 | 10 | ||||||

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Miss.Li

Phone: 18018319155

E-mail: lina@cybeltmachine.com

Whatsapp:86-18018319155

Add: No.6 Xinyuan Road, Jiangyin City, Wuxi City, Jiangsu Province, China